Origins

Hemingfield Colliery, also known as Low Elsecar Colliery, was developed for Earl Fitzwilliam in the 1840s, under the management of Benjamin Biram (1803-1857), his Steward, mineral agent and general manager.

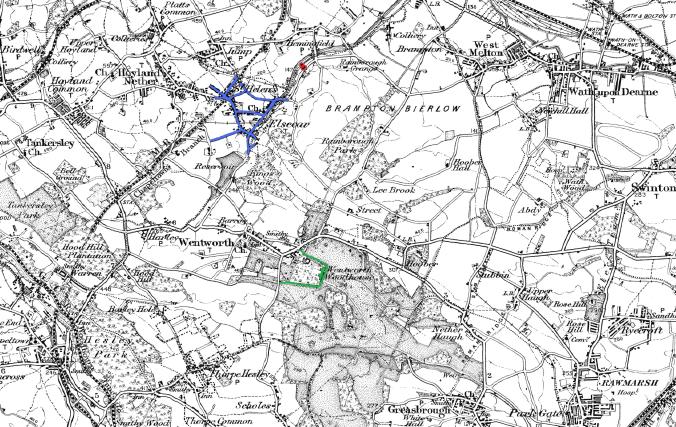

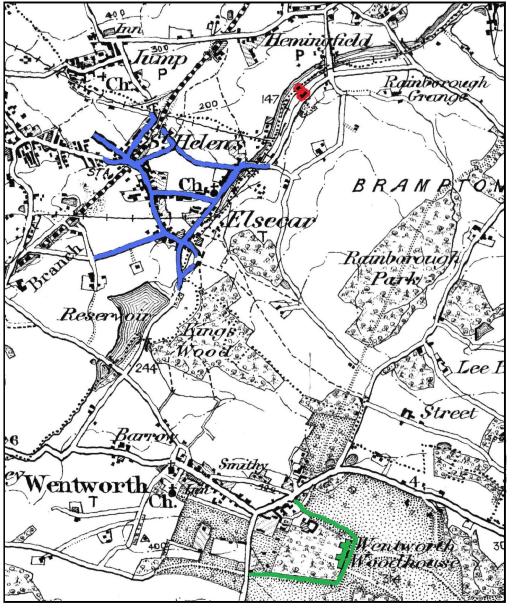

It formed part of the Earl’s Elsecar Collieries, consisting of Elsecar High, Mid and Low pits. Earl Fitzwilliam also owned a further extensive group of pits around Park Gate. Both groups were close to the heart of his South Yorkshire estates at Wentworth, as indicated on the map below:

Key: Wentworth Woodhouse marked in green. Main streets of Elsecar marked in blue. Hemingfield Colliery marked in red.

Detail of 1911 map: Wentworth Woodhouse, Elsecar and Hemingfield

Sinking the Pits

At Hemingfield, the work to dig out the shafts, known as ‘sinking’, took a number of years to complete after starting in earnest in 1842. The work hit a number of problems, with gas and water, before the winding pit finally reached the coal of the Barnsley seam in late 1847, at a depth of 157 yards. This seam, consisting of coal measures 9ft 5in thick was also sometimes referred to as the ‘Elsecar coal’.

When at work the Hemingfield Colliery consisted of several shafts, for pumping water from the pit, for winding coal, and for improved ventilation as the workings expanded further underground. The main working shafts were:

- Two downcast pits, each 468 feet deep:

i) a circular ‘engine’ or pumping pit, served by a 130 Horse Power Cornish engine, fired by three boilers and raising water in three lifts – two rams of 60 yards each, and a bucket lift of 35 yards.

ii) an elliptical 10ft diameter winding shaft worked by a 30 HP 22 1/2 inch vertical cylinder, 5ft 6inch stroke engine with flat hemp ropes (later flat wire ropes) over a winding drum 9ft 11 inches;

- One upcast shaft (really 2 shafts, but later joined into one at the surface) Sunk c.1852-3 to improve ventilation:

iii) a circular upcast shaft, of 9 ft diameter

iv) a circular upcast shaft of 7 ft diameter.

- An additional downcast, the new Rainborough shaft, 14ft diameter,175 yards deep in total, sunk 1864-5

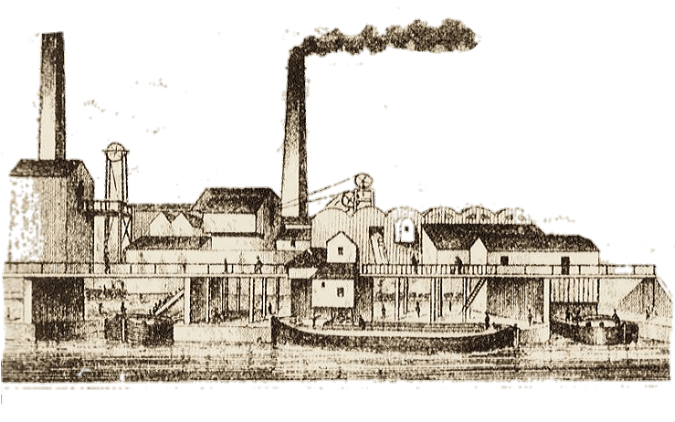

When first opened the colliery already benefited from a connections to the Elsecar branch of the Dearne and Dove Canal, with its own loading basin, the Hemingfield Basin which survives today.

Later the colliery also gained a connection to the South Yorkshire Railway, as the Elsecar branch was opened in 1850. Though removed in the 1980s, the end mile of track was relaid in the 1990s and still carries passengers as the Elsecar Heritage Railway which also offers footplate experiences for those wishing to fire and drive an engine.

Up to scratch

In 1851 the coal from Hemingfield colliery was sent to the Museum of Practical Geology to be tested for its suitability for fuelling Royal Navy steam ships. It was described as follows:

“The vein has a dip of 1 in 12 towards the north-east, and is usually about 9 feet in thickness. The overlying stratum is “stone bind” and the subjacent, fire-clay. The coal is worked in faces 40 or 50 yards in length. The principal market is Hull, which is about 80 miles away from the colliery, but large quantities are consumed by iron-works in the immediate neighbourhood of the mine. The present price is 5s 9d per ton of 21cwt.

[…] During the experiments it was found to light easily, burn freely, and get up steam rapidly; considerable quantities of ash were, however, produced, and unless the fire was frequently cleared, the draught became choked, and the clearness of the fire impaired.“

Museum of Practical Geology. Third Report on the coals suited to the Steam Navy

by Sir Henry de la Beche and Dr Lyon Playfair, London 1851 London: William Clowes and Sons, p.26

1852 – Disaster strikes

At 1.30 pm on 22nd December 1852 an explosion underground claimed 10 lives and injured a further 12 miners. An inquest followed, led by Coroner Thomas Badger, and the Mines Inspector for Yorkshire, Charles Morton admonished the management and the men, though the effects would have been significantly worse had the ventilation of the workings not been carefully divided in two districts under Biram’s guidance. Printed rules were thereafter required for the safety of the miners.

The Friends produced a booklet on the disaster of 1852, available for £2.00

After 1852 Hemingfield, like all of Earl Fitzwilliam’s pits, enjoyed a relatively good record of operations – though mining was by no means a safe profession as the yearly record of accidents due to roof falls testifies.

1850s-1920 – regular working and gradual exhaustion

The 1850s and 60s saw significant investment in improved ventilation to help cope with the dangers of gas as Hemingfield’s workings expanded. This included two additional ventilation shafts closer to Elsecar village, sunk shortly after the pit began working, and topped by a ventilating fan with boiler plant, engine house and chimney. In the 1860s a further large diameter shaft was sunk over towards Rainborough Grange to increase air flow in the workings.

View of Hemingfield Colliery fan engine house and Chimney looking from Elsecar.

Superintendence of the mines passed from Benjamin Biram to John Hartop (1815-1902) following Biram’s death in 1857. Railway contracts through the Great Northern and South Yorkshire Railway companies brought prosperity to the collieries, together with new customers in London and the south. Equally the growth of local ironworks at Elsecar and Milton under the Dawes brothers from 1849 guaranteed a steady demand for Elsecar coal. By 1869 Hemingfield was raising 500 of coal tons per day. Ten years later it was still the busiest of the three Elsecar pits then at work (the other two being High Elsecar and Simon Wood).

On 23rd July 1883 the old wooden pit headgear at Hemingfield was taken down. A new set was up by the 4th August, and coal winding recommenced on the 6th. John Hartop retired as General Manager in June 1886, being replaced by Thomas Newbould (1845-1933) on 1st July that year. Newbould had worked for Earl Fitzwilliam since the 1860s, becoming manager of the Low Stubbin pit in 1870 following the death of his uncle Thomas Cooper. He occupied a number of roles prior to his retirement as Agent and General Manager in 1920.

Thomas Newbould, General Manager of Earl Fitzwilliam’s Collieries from 1886-1920

His period of service spanned the closure of High Elsecar (1889), Simon Wood (1903), Hemingfield (1920) and Low Stubbin (1920) collieries as well as the new sinkings at Elsecar Main and New Stubbin at the beginning of the 20th century. Newbould was also present when the King and Queen visited Elsecar in 1912, and guided the King in a visit to the underground workings at Elsecar Main.

Thomas Newbould (left) with the 7th Earl Fitzwilliam, William Charles de Meuron Wentworth-Fitzwilliam (right) at Wentworth in 1911

Hemingfield Colliery ceased drawing coal for Earl Fitzwilliam on May 15th 1920 after which time the South Yorkshire Pumping Association took over the pumping at this pit, as well as further pumping stations at Elsecar and Westfield. The Association had been established by 15 local collieries who became alarmed at the flooding of old abandoned mine workings in the Barnsley seam – the Association was formed to tackle and prevent the impact of rising water on active and future working elsewhere in the district.

The initial group of 15 companies in the Association consisted of:

- Brodsworth Main Colliery Company Ltd (reg.1905)

- John Brown & Company Ltd (Aldwarke Main, Car House and Rotherham Main collieries)

- Bullcroft Main Colliery Company Ltd (reg. 1908)

- Carlton Main Colliery Company Ltd (est.1872; name changed 1900)

- Cortonwood Collieries Company Ltd (reg.1883)

- Dalton Main Collieries Ltd (reg.1899)

- Denaby and Cadeby Main Collieries Ltd (reg.1893)

- Hickleton Main Colliery Company Ltd (reg.1892)

- Houghton Main Colliery Company Ltd (est.1875; new company reg.1900)

- Manvers Main Collieries Ltd (reg.1899 taking over earlier company)

- Mitchell Main

- New Monckton Collieries Ltd (est.1874; reg.1901)

- Stewarts and Lloyds Ltd

- Wath Main Colliery Company Ltd (est.1876; reg.1901)

- Wombwell Main Company Ltd (reg.1865)

The three Fitzwilliam water drainage sites were finally conveyed to the Association on 4th October 1920. Prior to the Association’s installation of electric pumping equipment, the old Hemingfield Cornish pumping engine was able to pump ten strokes a minute, working 7 days a week, the total quantity being pumped was 30,000 gallons per hour.

Rees Roturbo Manufacturing Co Ltd supplied pumps to Hemingfield, Elsecar and Westfield Pumping Stations.

The first electric pumps installed at the pit bottom by the Association were a double set of 145 HP Rees Roturbo centrifugal pumps each capable of dealing with 600 gallons per minute which were later modified and supplemented by pumping equipment at the Kent’s seam.

In August 1929 the Pumping Association was put on a more formal statutory basis as the ‘South Yorkshire Mines Drainage Committee’ under section 18 of the Mining Industry Act, 1920 (Statutory Rules and Orders No.803 of 1929).

South Yorkshire Mines Drainage Committee

The scheme’s boundaries were amended in October 1936, and ten year later the Committee’s property and powers were absorbed by the National Coal Board under Schedule 3, Part II of the Coal Industry Nationalisation Act of 1946, described as “An Act to establish public ownership and control of the coal-mining industry and certain allied activities; and for purposes connected therewith.” it saw the nationalisation of the industry from 1 January 1947.

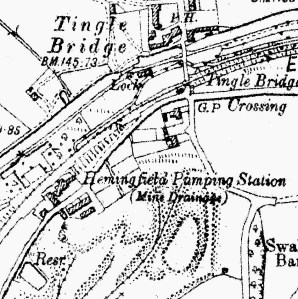

OS Map of Hemingfield, Emergency Issue O.S. map 1938

Functioning as a pumping station, under the South Yorkshire Mines Drainage Unit, Hemingfield would survive the next forty years quietly working away, a mute witness to the changing political landscape, and to the decline and fall of an industry it had once been spared to help preserve.

The remains of Hemingfield Colliery outlive its younger sibling, Elsecar Main Colliery which was just down the road. The first sod of the upcast shaft at the ‘new’ pit had been dug in July 1905, but the whole pit was finally closed in 1983, and demolished by 1987.

View of Elsecar Main Colliery, early Twentieth Century, looking across the Dearne and Dove Canal from Reform Row.

1920-1989 – Pumping station

In 1987 the NCB was rebranded as the British Coal Corporation (commonly ‘British Coal’) as the pattern of pit closures continued. The South Yorkshire Mines Drainage Unit closed and Hemingfield was managed directly from Silverwood Colliery. Pumping was finally discontinued in October 1989, though the site was retained as a pumping station by the South Yorkshire Group of British Coal.

1994 – Privatisation and the beginning of the end

The passing of the Coal Industry Act 1994 marked the end of nationalisation and the creation of a new, part privatised system – mineral assets and subsidence liabilities being assigned to the new Coal Authority, while the remaining commercial interests of British Coal Corporation were sold to a number of private companies. Hemingfield itself became the property of Central and Northern Mining Limited (est. November 1994). In December 1994 the new company which had taken on much of the UK’s deep mining changed its name to RJB Mining (UK) Ltd, and later still, in May 2001, it became known as UK Coal Mining Ltd.

Photographic artwork showing fire damage and neglect to switchgear building on Wath Road

Meanwhile the site itself was becoming overgrown and neglected. In the 2000s, it suffered from cable theft and vandalism, including significant fire damage to the switchgear building nearest to the road in September 2008. In December 2012 the UK Coal Group companies were restructured into Harworth Estates (dealing with property) and UK Coal Mining Holdings Limited, of which UK Coal Mining Ltd was a subsidiary.

Hemingfield Pumping Station in 2013

2014 – FoHC take over

In 2013, after a period of very public difficulties following a fire at Daw Mill Colliery, UK Coal Mining Ltd, a division of the UK Coal Group, went into administration. This led to the establishment of the Friends of Hemingfield Colliery (FoHC), and in December 2013 the group made an offer to purchase the site to safeguard it for the future. Subsequently the UK Coal administrators BDO undertook the winding up (a Creditors’ Voluntary Liquidation) of the company which had been renamed Juniper (No3) Ltd.

Hemingfield pit with its two remaining shafts and headgears was part of the property to be liquidated. The Friends offer was accepted, but the transaction was not completed until 27th June 2014. The group is now eager to press forward with its own plans to repair and refurbish the buildings and to redevelop the site as a visitor centre, with community and social enterprise initiatives to attract visitors and help fund further improvements.

Restoration work on the winding engine house in 2016

Repair work on rear retaining wall 2019

How can I get in touch with you. My father worked as a pony lad at Old Hemingfield from about 1914. Your photos don’t show some of the features which I remember.

Roy Broadbent {son of Herbert Broadbent}

01226 710406

LikeLike

Very interesting , especially to an 82year old man who lived in Hemingfield for many years

LikeLike

The pumping station house on wath road was run by my uncle Charlie an auntie may , I used to visit the house with my mom when I was a kid , I’m trying to trace back , my moms name was peach , our visits were mid 50s , the sons of May were do and Harry , think Harry married Doris , don I forgot , I’m now 72 so the sons would be in there 80s. My moms maiden name is olive peach , who moved to burton wood with her mother , I’d be grateful for any more info , thank you. Graham Phillips

LikeLike

Thank you

If you have info

LikeLike

MY GRANDFATHER TOM HAGUE WAS ONE OF THE LAST OFFICIALS OF HEMINGFIELD COLLIERY I THINK HE WAS EITHER A DEPUTY OR OVERMAN HE LIVED IN THE HOUSE THAT WAS BUILT FOR THE FIRST MANAGER OF THE PIT IT CAN BE SEEN FROM YHE PIT WHEN HEMINGFIELD CLOSED HE WENT TO WORK AT THE SKIRES SPRING ALSO KNOWN AS SLUDGE MAIN TWO OF HIS SONS MY UNCLES ALSO WORKED AT HEMINGFIELD.

MALCOLM HAGUE

LikeLike

I was just reading this to mum (Jean Cook (Hague) Was the Brig the house that the family all lived in originally built for the pit manager ? Many many memories of this house and Grandma Hague and Rex the dog.

LikeLike

Hi Deborah. Do you mean Pump House Cottage or the house on the little lane (up to what was Thief Hole, at Tingle Bridge?). Several people have suggested it was the managers house, although it may depend on what people see as the manager. The first hands on Manager at the time of sinking the pits at Hemingfield was William Goodinson who left by 1843 as James Uttley took over (they covered all of the Elsecar pits), neither lived there (they were in/around Cobcar). Later undermanagers, or fire-triers may have been closer, we are still investigating via the Wentworth Estate records at Sheffield. Would love to hear any memories though!

LikeLike

I have in my possession a letter dated 1860, regarding the sinking of a pit at Hemmingfield, The names appearing are, Geo Law, Mr Burks, and a Mr Carnley,, and poor families living at Rows Lane & Rows Close. Can you throw a light on this? S Phillips

LikeLike

Hi Stuart,

Merry Christmas. Many thanks for your comment. The pit you mention may have been a proposed working by George Law, coal proprietor, and sometime manufacturer of bricks, and something of a bon viveur (often appears in local papers in association with drinking). He had a colliery at Brampton/West Melton, taking it on from his father John Law. Mr John Birks was a solicitor, d. 1860, being succeeded by his son William. The Birks were landowners based at Hemingfield, and I would think it was Joseph Carnley who was a farmer, local landowner (later had a street named after him at West Melton). Would be interesting to know whether the letter is specific about the purpose of the pit as that date is near the start of the West Melton Waterworks Co. Ltd in which Law and Carnley were both interested. Law died in 1869 and was buried at Brampton Bierlow Church West Melton.

LikeLike

Wonderful insight into the history of this very important facility. I am pleased that the FoHC have stepped forward to protect and developn this Colliery which quiety played its part in the mining industry tthat fuel the Nation and put food on the tables and secured futures for many local folk. Keep up the great work I wish I lived nearer to take advantage of this society. A Wombwellian by birth and from many generations of miners but now a Texan with a funny accent who has never forgot his home and the Price of Coal and what it provided for me.

LikeLiked by 1 person

Hi Paul

Thanks so much for your message. Would love to hear more about your family history and keep in touch with developments back ‘home’.

FoHC

LikeLike

Note: Also posted in the South Yorkshire pumping section.

Hello,

This is all very interesting reading to me, an ex Elsecar lad and pit fitter living in New Zealand since 1995.

I left mining after Maltby pit went private in 1993 and we were (again) offered redundancy. Most of the ex Elsecar lads worked at Silverwood, Maltby or Barnbrough pits following Elsecar’s closure.

My Dad worked at Silverwood (after Cortonwood closed) and both my Mother and Grandfather worked at the “New Yard” or Elsecar workshops to give it its proper name, now Heritage Center of course. My other Grandad died down Skiers spring pit, I still remember the police coming and telling Mam, we lived on Grey Street in Elsecar at the time.

When Elsecar was closing I was tasked with setting up air and water supplies down in some disused workings (Westphalia board on the West side for any ex Elsecar Main guys reading this) for the Mines Drainage team to come in and build some air and gas tight dams before closure, anyway they must have liked me as I ended up working for them based in Parkgate, Rawmarsh which was the base, also a pumping station. Before and then after the strike we managed a couple of dozen pumping stations all over Yorkshire including of course Hemingfield. In fact me and another bloke Colin (an ex Elsecar pit welder) built the steel platform that still exists in the old concrete headgear there. This we set up to make safer access when setting up our gear to change the pumps, which I did twice or maybe three times. We used the old buildings for our “snap” time. My Dad was born in one of the cottages opposite Hemingfied pit too as it happens, I think it was farmland behind them before Elsecar pit tips took over!

Eventually our mines drainage (or “Small Mines” as we were known) work spent more time (sadly) filling closed coal mine shafts and eventually with no pits to protect we ourselves closed and I was offered the job at Maltby. I personally worked filling Yorkshire Main, Cadeby and several others I can’t remember in West Yorkshire, there were a lot. We also set up the shaft to make safe for visitors at what is now the Yorkshire mining museum at Caphouse pit, I took my Kids there a few Years ago, it’s fantastic.

Happy to discuss more if anyone is interested.

Lastly thanks from me personally for all your work and efforts keeping this and other History alive in the area, it really is fantastic.

Thanks

Kevin Beardshall

LikeLike

Hi,

Thanks so much for your fascinating comment, we would certainly like to learn more about your memories and experience if you’re able to spare the time. Hope you’re keeping safe in NZ, but we will be in touch shortly! Thanks again!

LikeLike

Hi,

My mother recently passed away and as I live in Australia and couldn’t travel for her funeral, I decided to write a memorial and trace her family history.

I found that James Utley 1796 -1862 was my 3rd great grandfather and his son David Utley (1823 -1870) and wife Ruth Waring (1823 -1892) produced my great grandmother Mary Utley (1853 -1892).

During my research, I found that in January 1853 James Utley’s grandson, Allan Cocking who was 10, fell under the engine beam works and his head was crushed, dying instantly. This was in the London Morning Post, Saturday 15th January 1853 on page 8.

In 1841, James Utley and his wife Eliza lived at Nether Haugh with children Mark age 25, an Iron miner, David age 15, a blacksmith, Jane age 15 and James age 10.

In 1851 James Utley was living at Cob Carr and in 1861 lived at Cobcar Road.

I would really be delighted if there were any photos of these people in your records that I could see.

Whenever we can travel again, my husband and myself will come to Elsecar and find these streets and walk in our ancestors footsteps. Maybe I can find graves too.

Your articles, photos and maps are really interesting and have much much more to learn about the working lives of these miners and the social history too.

LikeLike

Hi Helen, thanks for this information. Would be great to welcome you to Elsecar, there are certainly some Utley graves in/around Elsecar. Will keep looking for any photographs. James Utley’s voice can be ‘heard’ via evidence he gave at inquests and events reported in newspapers, but also seen in his letters to Benjamin Biram in the Wentworth Woodhouse Muniments in Sheffield Archives. Yes, still so much to discover! Can certainly include more on them. Hopefully on lives and work and not just on the sometimes gruesome accidents! Thanks!

LikeLike

Thank you for your reply. Can I find these letters that James Utley wrote to Benjamin Biram online or do I have to visit the Sheffield Archives? I have read a few of the newspapers relating to inquests after mining explosions but would rather dwell on something more uplifting!

LikeLike

Hi, I think the letters am thinking of are in the correspondence in the Wentworth Woodhouse Steward Papers 15, which are arranged by years and alphabetically, so under ‘U’, but he worked for Benjamin Biram, so passing refs in WWM/Stw P/14-18 which are on microfilm in fact. We may be able to dig out some transcriptions, a couple of snippets to hand are working replies to BB:

25/9/1856

WWM StwP 15 (xxviii) U-60

25 September 1856

Sir, I am sorry that I disobeyed orders in stopping the fan at the Mid Twin Pits. The reason I stopped it was this- I went down to the pit about 8 o’clock in the morning and found some of the colliers on the hill and they had ascertained by some means that this fan made less air than the furnace and they appeard dissatisfied with the fan consequently I ordered the furnace to be set on.

I ordered the fan to be set on yesterday morning and it is now working without the furnace…

24/12/1856

WWM StwP 15 (xxviii) U-63

24 December 1856

Sir,

The fan at the mid twin pits broke down this morning it worked yesterday afternoon and last night until about 6 o clock this morning when all the waffers but one broke out.

We are without waggons at all the pits. I wish you would write to Mr Middlemese about sending some Your obtd servant, James Utley

But also, (misspelled) you can see a nice quotation taken by Government inspectors, based on his assessment of the local community here: https://books.google.co.uk/books?id=oBRcAAAAQAAJ&pg=RA1-PA25#v=onepage&q&f=false

LikeLike

Thank you so much for taking the time to reply and also sending the messages from James Utley to Benjamin Biram. All so interesting to discover about these people.

I read the link about Earl Fitzwilliams collieries and was so pleased to hear that he provided such a supportive environment for his workers and families and to know that my ancestors had decent living conditions with a caring community enveloping them.

Do you know if any photos exist of James Utley and his family? Thank you once again for your time.

Kind Regards,

Helen

LikeLike

Hi, we are not aware of photos directly, but will see if we can find any.

LikeLike

Pingback: Industrial Heritage Photography Course Sheffield South Yorks

Doing my family tree. My father, born in 1912, was named after his uncle, Frederick Butcher, who died in an accident at Elsecar, aged 19, in 1910. His stepbrother also died in a mining accident, aged 18. They lived in Hemingfield. Great to find your site and see you keeping history alive. Definitely visiting on our next trip to the UK from Spain.

LikeLike

Thanks. Allison. Would be pleased to hear about any further findings. If we can assist in searching also let us know.

LikeLike

My late father spoke of a relative who died as a child/teenager in an accident whilst playing on the slag heap at Elsecar colliery. Probably in the 1920s or 1930s and the family probably lived at Jump. Can anyone help me with information.

LikeLike

Hi Philip, Elsecar Main spoil heap? could try and look for references, do you know any more name details to help look for/pin down a date? Friends of Hemingfield Colliery

LikeLike

Hi,

The only other thing I know is that my fathers relatives at Jump were called North.

LikeLike

Hi, Thanks. Ah. It looks like ot will be Feb 1936, and A 56 year old gentleman called Frank North, of 23 Kitroyd, Jump. Newspaper report is available. Could email.

LikeLike

Yes that is the area they lived.

Please email me the report.

Thank you,

Phil.

LikeLike

im looking for my daughters grandads records re his pit days, his father was called frank oldknow they lived in 61 and 53 cemetary road. frank was at platts field and his son a pony boy.any information would be good also thomas. thank you

LikeLike

Hi,

Do you know roughly what dates they worked there?

LikeLike

approx 1917, he was born in 1907 so im guessing they worked from the age of 10?

LikeLike

Thanks we are checking record. Probably would only have been allowed to work from 13 at that time (after the passing of the Mines (Prohibition of Child Labour Underground) Act 1900).

LikeLike

Probably would have to be 13 after Mines (Prohibition of Child Labour Underground) Act 1900 was passed.

LikeLike