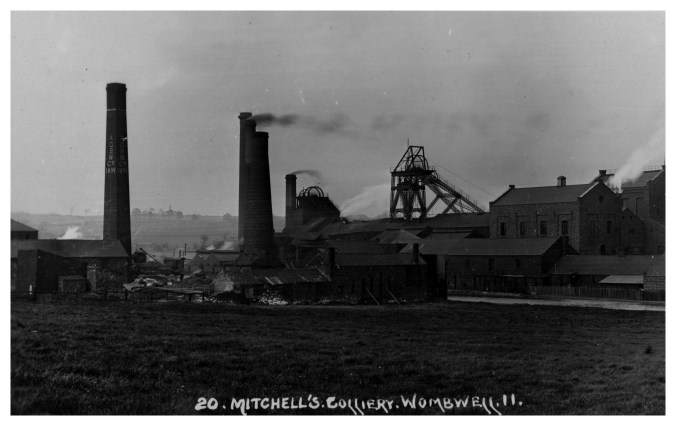

The Winning of Coal at the Mitchell’s Main Colliery.

Grand Banquet and Great Rejoicings.

On Tuesday last there were considerable rejoicings that the Mitchell’s Main Colliery, near Barnsley consequent on the winning of the thick coal. The South Yorkshire coal-field, it may be said, is one of the finest in the kingdom, and has made more rapid strides, so far as its mineral production is concerned, than any other. It contains, in addition to others, the well-known Silkstone and Barnsley thick coals, the latter seam varying from eight feet to ten in thickness. There is little or no parting in the seams, and it is adapted for almost every purpose, the hards being an excellent steam coal, and well adapted for coke-making; whilst the softs are used for household and gas purposes. At Mitchell’s Main the seemed is eight feet in thickness, and the quality is equal to any to be found in the district. […]

The area of the field already leased by the proprietors of the Mitchell’s Main Colliery is 450 acres, which will yield of the Barnsley coal something like four million tons. This colliery, the Mitchell’s Main, may be termed an international one, for it is owned by an English and a French gentleman, the latter being the well-known Mr. Josse, the great coal shipper of Grimsby, and who is also connected with Mr. Worms of Paris, Lyon, Geneva, &c., the largest continental importer of English coal there, his average purchases exceeding a million tonnes a year. It was under such circumstances that our visit to the works on Tuesday, we saw the English and French flags floating together from the highest part of the colliery gearing.[…]

It may be stated that the pit is very advantageously situated, being sunk on a plot of land at Aldham Junction, between the Manchester, Sheffield, and Lincolnshire Railway and the Dearne and Dove Canal. The surface plant has been laid out with great care, and in connection with it have been introduced all the most modern appliances, including powerful engines capable of drawing 1000 tons of coal per day. […]

Mr. Joseph Mitchell, Jun., then read a report relating to the sinkings and the various changes which had taken place. The report was to the following effect:- The first sod was cut on August 3rd, 1871, by Mrs Mitchell. The original contract was let to Messrs Jagger, Taylor, and Wigglesworth, but, when about 30 yards had been won, soon after the work was stopped for more permanent pumping engines, and in November, 1873, the mangement was placed in the hands of Mr. Joseph Mitchell jun., as engineer, and has continued down to the present time. The shafts are each 13 ft. 6 in. in internal diameter. During the sinkings, about 1,800 gallons of water per minute had had to be contended with for a depth of 135 yards before it was successfully tubbed back in the upcast pit 122 yards ofv tubbing were inserted and 130 yards in the drawing shaft. In the course of the work two faults have been crossed. The coal had been won in one of the shafts at a depth of 307 yards from the surface. The coal, which is of a very superior quality, is 8ft. in thickness. The sinkings in the upcast shaft are 212 yards deep, and it was expected the sinking in this shaft will be got through by the month of December next. The sinkings in the upcast shaft were delayed five months to allow for the getting in of tubbing and to sink through the water giving measures in the drawing shaft. The main of the pumping operations had been carried out in the upcast pit. The sinking was done by the day, while the water had been got through and tubbing completed. Afterwards, the sinking of the drawing shaft was contracted for by Messrs. Joyner and Stead. The upcast pit was contracted for by Messrs Knott, Clarke, and Thompson. It was intended to ventilate the mine by means of one of Guibal’s patent ventilators, which was now being made at the foundry of Messrs. Mitchell and Co. Limited, Worsbro’ Dale, where the machinery and appliances had also been made. The engineers could not speak too highly of the efficient services rendered by Thos. Bennett, the master sinker, and George Ward the enginewright.

Barnsley Chronicle, Sat 18th Sept 1874

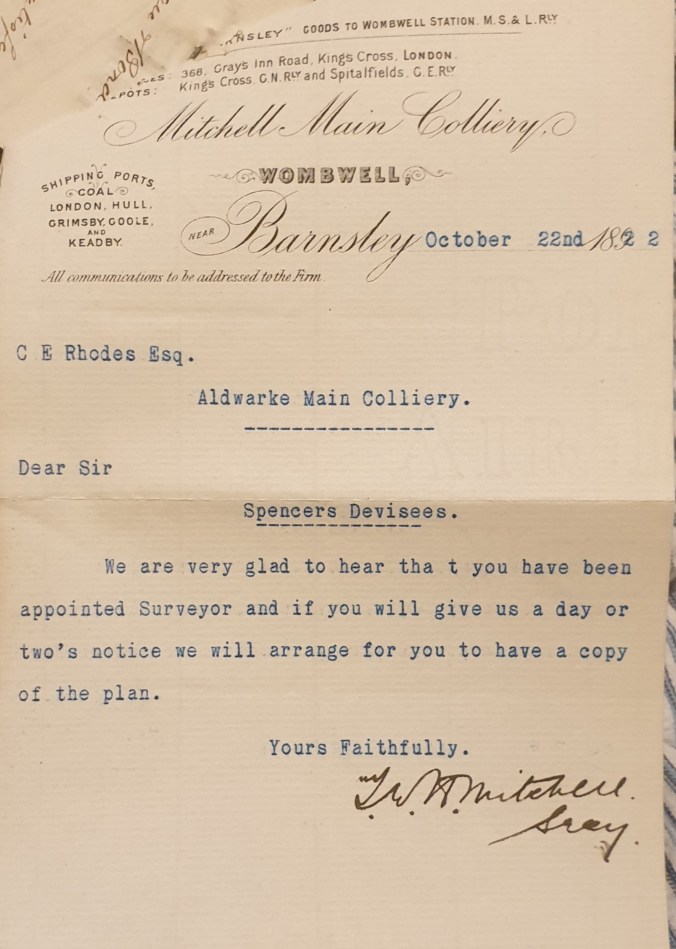

Typescript letter from the Mitchell Main Colliery Secretary from 1892