As part of celebrations for ten years of work at Hemingfield Colliery, formerly a pumping station, FoHC Chair Steve Grudgings shares the results of some of his historical research into the working history of the National Coal Board’s Mines Drainage Unit (MDU) in 1955. Steve writes…

Introduction

It was 19 years ago (2005) that I parked outside the Westfield Newcomen Engine House at Rawmarsh and loaded up my old Skoda Octavia will a carload of “souvenirs” retrieved from the top floor of the building.

With hindsight, I realise it had been used as a storeroom for materials previously housed in the offices (100 yards up the road) and the workshops (adjacent) at Westfield. These presumably had been transferred when the NCB’s Mines Drainage Unit (MDU), based at Westfield had closed in 1989, and the premises rented out to new tenants.

1955 Diary

One item retrieved was a 1955 diary listing the MDUs daily activities and sites.

Given the absence of archival data describing their work during this period, I thought that after 15 years, I should examine it to see if I could make sense of the unit’s work at that time. Whilst the handwritten entries are not easy to read, there are at least four weeks of blank pages and the diary ends prematurely at 9/12/1955, it has been possible to work out some of the unit’s activities, and my understanding of the main ones are set out below.

The NCB’s South Yorkshire Mines Drainage Unit

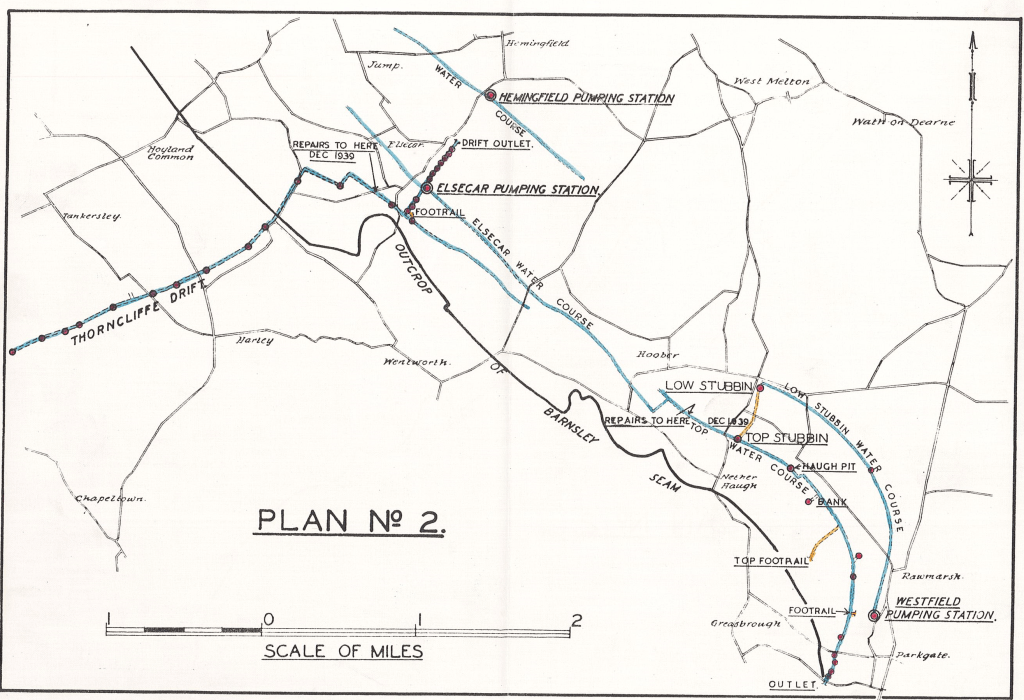

Following nationalisation of the Coal Industry in 1947, the MDU had taken over the work of the South Yorkshire Mines Drainage Committee (SYMDC), much of which was a continuation of what had been done previously by the South Yorkshire Pumping Association from 1920-1929.

It’s task was to maintain and repair the shafts, adits and watercourses by which water was removed from the abandoned coal seams, mainly but not exclusively those concerned with the Barnsley Bed, to prevent its descent into the deeper workings below.

SYMDC had operated under a tightly-controlled brief whereby the colliery companies whose workings it protected paid its costs on a proportional basis based on their working tonnage. With nationalisation, such controls were dispensed with, and the MDU’s work expanded across much of the NCB’s Yorkshire area, the unit apparently being called on whenever shaft repairs and temporary pumps were needed. Their extended geographical range is reflected in the diary.

Typical activities in 1955

Diary entries are made on a daily basis, with the first always being a summary of the main activities in the Westfield workshops. This is followed by brief entries for each of the sites visited on that day, often only a line summarising the day’s main activities.

The majority of their work appears to be concerned with routine examinations, clearance of watercourses, repair and replacement of pumps and repairs to pumping shafts, insets and pump lodges.

We don’t yet know precisely how many men worked for the MDU, but in 1955 but its subsequent scale suggested numbers between 20 and 30. There would have been a small office staff of perhaps 5, and the rest would have been trained and experienced colliers, many of them qualified deputies. This qualification certified that they were competent with an additional set of safety related skills that allowed them, amongst other duties, to test for gas – crucial in old workings. The nature of their work and the conditions underground are difficult to understand 65 years on, but were clearly unpleasant, arduous and dangerous.

What follows is a site by site summary of some of this work, with a particular focus on the non-routine tasks. The most frequent activity reported for all sites is excavating and setting steels, i.e. digging out the spoil and falls from underground roadways and passages and installing semi-circular steel reinforcing rings.

This work is normally preceded by an entry in the Westfield workshops for cutting and drilling steels, suggesting each batch of steel rings was custom made in terms of length and curvature depending on the shape and size of the roadway. Drilling was needed for the bolt holes, which had to be aligned when bolted together.

The Sites

Westfield

The workshop complex, the engine house and headgear still exist today and are used for light industrial purposes. The MDU offices at Westfield House had been purchased by SYMDC in the 1930s and still exist a hundred or so yards up Westfield Road, now serving as a care home.

In 1955 the Newcomen Engine House, originally built in 1823, at Westfield served as a pumping station in its own right, raising water from the shaft into the Bottom (Low Stubbin) watercourse. The engine it contained having been decommissioned and scrapped around 1934. The nearby Westfield No 1 footrill gave access to both this and the upper complex of watercourses via cross measure drifts.

These lengthy parallel watercourses ran in a north westerly direction from Westfield draining the area between Rawmarsh and the Elsecar Valley.

Many diary entries refer to motors, winders and pumps being rebuilt and repaired and there was much steel fabrication and electrical work too. Specific activities include:

- In April and May 1955, the diary records construction of a headgear for the Milton Roadside shaft on the Thorncliffe Drift. This was then dismantling before being transported to site on 23/4

- The unit appears to have had a couple of lorries (one registration was EET257 and another EET530) and vans and apparently a Ruston Bucyrus RB 19 excavator, which was under repair in February. In March the latter was at Strafford with it’s air receiver taken to Westfield for testing

- Equipment such as mobile winders, cement mixers etc would have needed repairing and maintaining too. In January they report that the H&T (?) Engineer was repairing the 110HP pump which on 26/1 was returned to the works by BRS (does anyone remember British Road Services?).

- On June 3rd they are capelling 85yds of ¾” rope ex digger for the 20HP pikrose ( a proprietary name for a small haulage engine) for Wentworth Silkstone” – it was delivered there the following day.

- We know that the unit was capable and equipped to repair small colliery railway locomotives too. They made a workable loco from a pair of Ruston & Hornsby narrow gauge diesils locos being sold for scrap in 1947 for construction of Wentworth Drift mine is described by Adrian Booth in Industrial Railway Society Record No 103

- There are references to repairing gates, redecorating and repainting cottages, presumably some of the MDUs local buildings, the headgear also received the painters attention on 8/2.

Hemingfield

The picture that emerges from the diary is of regular visits here with the main activities being weekly underground examinations requiring access to the pump lodges and various repairs and maintenance to the pumps .

Elsecar and the Thorncliffe Drift

Elsecar pumping station warrants surprisingly few mentions, possibly their needs were met by the adjacent NCB workshops and Elsecar Main Pit. In 1955, the MDU appear to have initiated a project to clean and repair the lower section of the Thorncliffe Drift and the local activities seem to be concerned with securing the various shafts accessing the watercourse (into which the water is pumped at Elsecar). This work included:

- On 12/1 they report examining the drift from the outlet (near Hemingfield) to Milton.

- In August, Westfield workshops are building shuttering for concreting work in the ladder shaft (adjacent to the Newcomen Engine House and giving access to Thorncliffe Drift) and in September 2nd the MDU are concreting the drift shaft top here.

- The petrol engine in Crowther’s shaft (which was still open in 1990) is being dismantled and rebuilt between the 2nd and 5th of September and the Welfare shaft has its cap concreted on the 9th.

- On the 12th September the Plantation shaft (upstream from Crowthers) has its top capped, and the next day the adjacent Elsecar footrill shaft is also capped. All these shafts are in close proximity around the current Heritage Centre, none being deeper than 40′.

This work on the shallow shafts appears to be linked to a major programme centred on Milton Roadside shaft some 1000 yards upstream following January’s initial explorations (implying it had been blocked for some time) and for the next couple of months work excavating and setting steels is recorded.

In April, work at Milton roadside includes erecting the headgear built at Westfield, installing a 25hp winder and preparing the shaft including fitting timbers in a bailey bridge section in June.

Later in June they are laying the tub road and in July building a gantry and tippler, perhaps to clear accumulated deposits from this section of the drift (it was blocked and could not be travelled, presumably the reason for the work). The winder is still under construction on 4/8 when they report they are preparing for ventilation. Milton Roadside Shaft is on higher ground, 155’ above the Thorncliffe Drift water level hence the need for a proper headgear.

In September they are excavating shaft bottom and driving towards Milton House, the breakthrough to which is reported in October. They drove downstream because to do otherwise would risk being drowned by accumulated water.

Flockton Lane End

This pumping station in West Yorkshire had an almost daily entry and was probably the site furthest away from Westfield. It was a long established pumping shaft, draining a wide area of old workings south of Caphouse Colliery (today’s National Coal Mining Museum for England). The pumping engine house bob (beam) wall and capped shaft can still be seen today (2020).

The MDU men spent considerable time here, the shaft would seem to have been in poor condition and needing much repair work. The work described included installing and maintaining the new pumps.

Strafford

This pumping station was another frequent entry, and was some way to the west near Silkstone. Like Lane End, much effort went into repairing the shafts and pumps. On 5/2 the entries for Westfield record welding to Strafford hoppit telling us how the men accessed the shaft.

In October they used the MDU’s mobile winder to install new pump pipes in the shaft. There are a number of entries in Jan and Feb for repairing the water shaft, I am not clear if this is the pumping shaft or a separate one for water storage.

Whilst on the subject of mobile winders, in the 1930s the SYMDC purchased a small lorry-mounted mobile winder to facilitate access to the number of shallow shafts they were responsible for on the various watercourses, and this may have continued in use into the 1950s.

Low Stubbin

This was an old pumping station a few hundred yards North of Westfield, and another regular location, its shaft being used to gain access to the deeper of the two parallel water courses that drained the Barnsley seam there.

In January they were installing cables in the shaft and getting ready to send the winder to Low Shops. Low Shops was a closed J.J. Charlesworths pit in between Wakefield and Stanley Ferry, used as a workshops and presumably able to handle work that was beyond Westfield’s capability.

On 19 January (following a shaft inspection on the 13th – the only mention so probably being opportune) the portable winder was being repaired at Low Shops and on the 25th it was collected and installed at Low Stubbin. Low Shops site does not feature again in the diary

- On 10 May they are preparing three (sheer?) legs for unloading a winch and also repairing the lorry winder (it’s unclear if this is the same one repaired at Low shops).

- In July they report clearing the road (watercourse) to Top Stubbin ( north of Low Stubbin) and later that month fitting hanging chains and a detaching hook and new indicator bell – these would suggest there was a permanent winding installation here complete with cage and signals.

- In August and September Low Stubbin is reported as being damped off, I wonder if this meant gas levels had prevented access, possibly due to the long burning underground fire around the adjacent Haugh Pit?

- In October collection of the fan from Milton is recorded (presumably no longer needed following the Thorncliffe Drift breakthrough?) for installation at Low Stubbin. On the 14th, the diary records cleaning the road in the Oatwood Level (on the Bottom Water Course)

Carr House

The colliery here, just on the north side of Rotherham, had closed before nationalisation and the site converted into one of SYMDC’s pumping stations. It was active until the 1990s, and the remaining buildings were demolished in 2014.

Regular entries for the site all point to routine inspections rather than the remedial projects underway at Strafford and Lane End. In February they report repairs to the Well shaft and in April concreting the overflow trench.

Bore Hole

There is a lot of activity at the “bore hole”, its location is not described but I suspect this was at Barbot Hall near Greasbrorough where a borehole and submersible pump were installed and a small electrical switchgear house served by a lightweight headgear.

It is obviously a wide borehole as a 165HP Beresford Pump was installed in April and the following month shaft doors were installed. In July they delivered and fixed the winch and rope for the Pikrose, an electric motor presumably used for raising and lowering pumps and pipes in the borehole. Much of August and September was spent clearing out the shaft.

Waleswood

This colliery to the south east of Sheffield closed in 1948 and was adapted as a training pit and pumping station, and not finally demolished until the 1990s.

The MDU were busy repairing the Hazel Drift in May and Barnsley pit bottom in June but no further activity was recorded until 30/11 when they reported. Repairs to remove old rising main from surface to Hazel (seam) leaving Hazel to pit bottom in to conduct Hazel water to bottom. Wiring signals in UC shaft after all wire had been stolen!”

Skiers

This was both an opencast and deep mine site in the NCB era, and the MDU delivered 16 pipes to stores here on 28/1 and reported digging cable trenches and the dismantling and return of the Pikrose the following month.

Shafts and Watercourses

There were a number of sites on the Top Watercourse discharging at Mangham that the team worked on. It was reported on 4/1 that work had been completed on the Top Water Course and that they had travelled from the outlet to the Fire Wall (presumably where the underground fire had been sealed off since the previous century).

- The Mangham outlet at Parkgate was being repaired for much of the summer and they are “loading muck away to outcrop” on 8/7

- In July they are repairing Low Deep shaft top where the lock had been broken and sleepers thrown down the shaft. This shaft is at the southern end of the Top Water Course and had obviously been closed some time ago and its top covered.

- Mangham Shaft is being capped on 14/9 and steels being set the next day.

There are other sites that get one or two visits and these include East Ardsley (south of Leeds), Hatfield Borehole, installation of a temporary pump at Goldthorpe and transport of a pump to Wheatley Wood. The unit also installs what appears to be a submersible pump at Walton Colliery (Wakefield) in late June and July.

It’s also clear from the occasional diary entries that the MDU worked closely with local pits such as Silverwood, Nunnery and Cortonwood for supplies of materials and for workshop activity beyond their capacity. The withdrawal of 30 and 65hp pumps from Cortonwood is also reported on 22/8, I wonder if this refers to the end of pumping at Greenlands shaft between Cortonwood and Hemingfield?