114 years ago, in July 1911, the Society of Chemical Industry held their Annual General Meeting at Sheffield.

On Wednesday 12th July, members gathered at the Cutlers’ Hall to begin proceedings before a meal at the Grand Hotel.

Their gathering also included visits to related industrial sites, including local factories, collieries and ironworks. This post explores a couple of the highlights relevant to South Yorkshire’s industrial history with a focus on areas close to our own.

Times change. Or perhaps not…

In a world of doom and gloom for the current state of things, and perhaps of nostalgia for a lost golden age, it’s always interesting to see how contemporary South Yorkshire folk viewed their own area. As the handbook and guide for the Annual Meeting had it:

“From the railway the traveller certainly sees the worst of Sheffield, and is apt to associated it for ever in his recollection with a vision of mean and grimy back streets, chimneys great and small, furnaces and smoke – particularly smoke. Yet Sheffield is not as black as it is sometimes painted, and during the last year or two has achieved quite a record among large towns for sunshine. Though the character of the staple trades of the city disfigures it, the beauty of its suburbs to the west and south has long been a source of admiration to its visitors, unprepared for such a contrast between the city and its surroundings.”

Society of Chemical Industry, (edited by E.A. Smith), Handbook for the Annual Meeting, Sheffield, 1911, Sheffield: J.W. Northend, 1911, p.17

Industrial South Yorkshire

On the afternoon of the first day, Weds 12th July, the works tours focused mainly on Sheffield itself, including a trip to Tinsley to visit the Sheffield Simplex Motor Works.

On Thursday morning a party departed from Victoria station at 10.15a.m. for a whole day excursion, visiting Messrs Newton Chambers & Co. Ltd, before continuing to the Wharncliffe Silkstone Colliery Co.Ltd at Tankersley.

A separate half day tour also left Victoria station at 2.35pm to visit Parkgate Iron and Steel Co. Ltd near Rawmarsh.

EXCURSIONS

The text below is quoted from the 1911 Handbook & Guide, illustrated with other material for clarity:

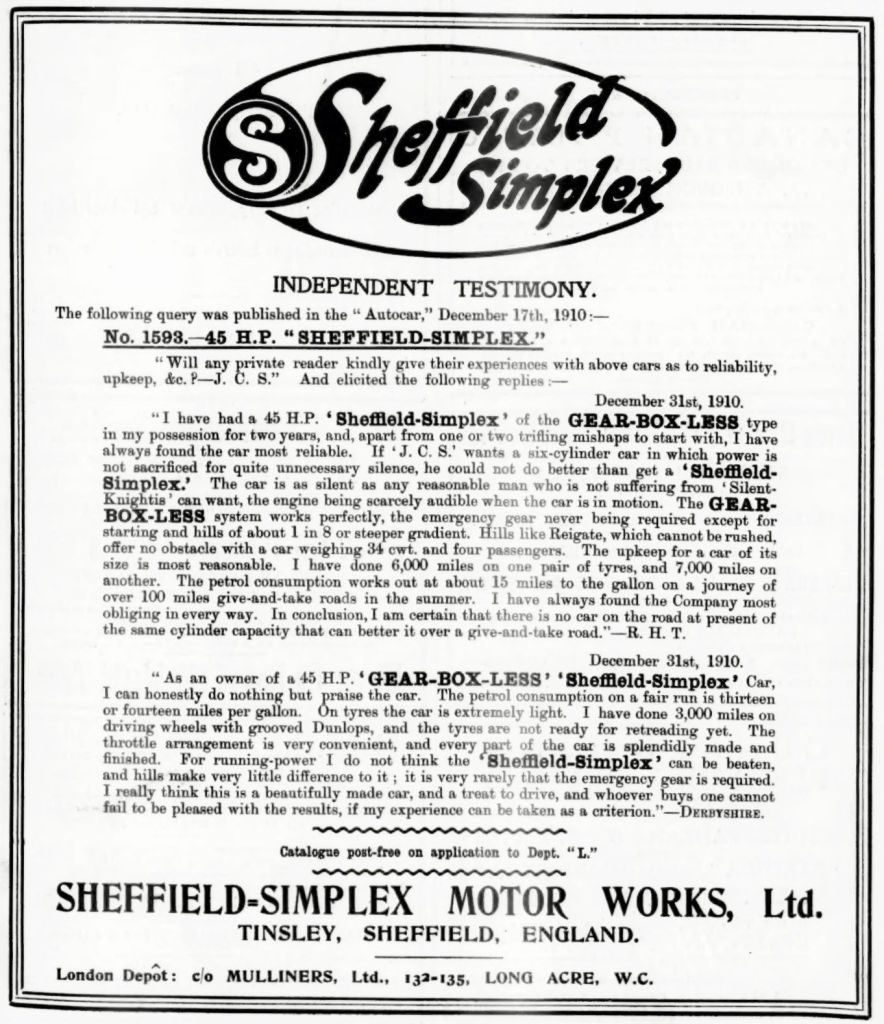

Sheffield-Simplex Motor Works, Ltd., Tinsley

These works are situated on the main Rotherham road, at Tinsley. Built some five years ago [1906] they are equipped in the most up-to-date manner for the manufacture of high-class motor cars.

Sheffield-Simplex cars right from their introduction have been eminently successful, having obtained an excellent reputation, and are to-day recognized as the finest examples of motor engineering extant.

The close proximity of the works to Sheffield – the centre of the world’s steel industry – has enabled the Company to conduct a close research into the properties of various steels specially suited for use in automobile construction, and this fact they have taken full advantage of, which is reflected in both the prices and quality of their cars.

Although not exceptionally large in size, the factory is replete with the latest machine tools and appliances especially designed for the intricacies of motor-car work, whilst only the very best skilled labour is employed.

A speciality of the Sheffield-Simplex Motor Works, Ltd., is a Gear-Box-Less car, which has earned for itself a remarkable name in the motor world for reliability, hill-climbing capacity, and smooth running under all conditions.

In fact the Sheffield-Simplex is the only car on the market in which it has been found unnecessary to incorporate the orthodox gear-box, that is, in this particular model.

Only six-cylinder cars are manufactured, of 25 h.p. and 45 h.p. respectively, the demand for which is increasing daily, and all over the world Sheffield-Simplex cars are now in use.

H.M. The King when Prince of Wales used a 45 h.p. Sheffield-Simplex car for his tour in Cornwall and Devon, and the firm possess a letter of testimony appreciative of the merits and fine behaviour of the car during that tour.

At the works may be seen the cars in course of construction, from the unfinished material to completed chassis and cars ready for testing and delivery to clients.

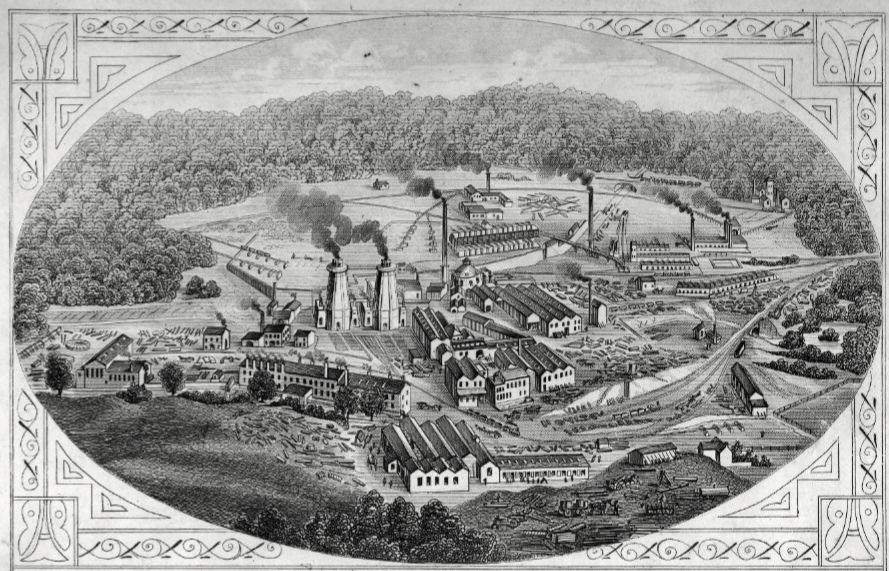

Messrs Newton, Chambers & Co. Ltd. Works at Thorncliffe and Rockingham

This firm have existed for 120 years as Ironfounders and Colliery Owners. They employ 6,000 hands and raise over one million tons of coal per annum. They are also considerably interested in the Chemical Industry.

Disinfectant works

Izal disinfectant fluid is an emulsion containing 45% of izal oil. It has a germicidal power as high as any known emulsified disinfectant; the special form of emulsification enables it to be mixed in any proportion with hard or salt waters or with organic fluids.

Izal oil itself is the product of a special type of coke oven, which yields a tar containing little, if any, benzine, naphtalene, anthracene, or carbolic acid. This tar is distilled, treated with soda, and finally fractionated and refined, the final product being a clear yellow oil, of which 90% distils between 205° and 350° C., with a specific gravity of about 1.040.

One of the chief features of the finished product is its freedom from carbolic acid and cresols and its non-toxic character. A recent research upon Izal by Professor Proskauer, of Berlin, has shown that undiluted Izal can be introduced into the stomach of animals without harm, and that rabbits easily tolerate doses as large as 1 gramme per 100 grammes of rabbit.

In addition to Izal the works produce veterinary Izal, toilet, bar, soft, and liquid soaps, Izal disinfectant powder, cream, embrocation, and various Izalized products for the use of medical men, veterinary surgeons, farmers, &c..

Rockingham Koppers Ovens

This battery of 30 retort ovens has been working for two years, and an additional 15 ovens will shortly be ready. The original battery carbonizes 1,100 tons of coal per week. The coal is damped and stamped into a cake, which is pushed into the oven by electric power, and an electriclly-driven ram similarly discharges the coke.

The latest type of coolers, exhausters, washers and scrubbers are installed, together with tar stills, crude and rectifying benzol stills, and ammonium sulphate plant.

The surplus gas feeds a 500-h.p. Mather and Platt gas engine, and provision is made for the addition of a second one. The electric power generated by this engine is carried to two collieries and used for various purposes above and below ground.

Tankersley Joint Colliery Rescue Station

The Tankersley Rescue Station was established in 1902, chiefly on the initiative of Mr M.H. Habershon and Mr George Blake Walker, and is now supported by Newton, Chambers & Co., Limited; the Wharncliffe Silkstone Colliery Co.; Barrow Hematite Steel Co.; Earl Fitzwilliam’s Elsecar Collieries; and the Stafford Collieries Co. Limited.

At this Rescue Station men are regularly trained in the use of breathing apparatus, which enables them to work underground in irrespirable atmospheres, the conditions being artificially reproduced in the experimental gallery of the station.

The men are trained in ambulance work underground, and the Draeger and Meco type of breathing apparatus is always kept in readiness day and night.

The Wharncliffe Silkstone Collieries, Tankersley

There are two main drawing shafts: the No.1 Pit, 165 yards deep, 12 ft. diameter, sunk to the Silkstone seam, from which is drawn the Parkgate, Thorncliffe thin, and Fenton coal. The No.4 Pit, 225 yards deep, 14 ft. diameter, from which is drawn the Silkstone and Whinmoor coal. The output from these shafts is about 10,000 tons a week, to which No.1 Pit contributes about two-thirds of the total tonnage.

About 100 tons a week are drawn from the Lidgett seam at Knoll Drift day-hole. About 200 gallons of water per minute are pumped from No.1 Pit bottom by direct-coupled 6-stage centrifugal pumps.

Winding Engines

No.1 Pit vertical engine, cylinder 33 in., 5ft. stroke; diameter of drums, 12 feet. The cages hold four tubs of about one-third of a ton capacity; the shaft has wooden guides and locked coil winding rope 3¾in. in circumference. No.4 Pit, horizontal cylinders, 26″ diameter, 5ft. stroke, 14′ drum, rope guides.

Ventilation

Produced by a Schiele fan 12′ 6″ diameter, belt driven by a horizontal engine, 33″ cylinder, 3 ft. stroke, with vis-à-vis spare cylinder. The quantity of air in circulation is about 160,000 cubic feet at 4″ water gauge. There is an auxiliary fan at No.2 Pit drawing about 25,000 cubic feet of air at about 1.5″ water gauge.

Haulage

In No.4 Pit is by endless rope both under and over the tub. In the No.1 Pit, chiefly main and tail, there is a large electric haulage (150-h.p.) underground.

Generating Plant

Driven by waste gas from the Simon Carvès by-product ovens, and consists of four units:

A) 300 B.H.P. Mather and Platt 2-cycle engine.

B) 350 B.H.P. Robey 4-cycle engine.

C&D) 200 B.H.P. Hornsby Stockport vis-à-vis 4-cycle engines.

A 70-h.p. Crossley gas engine drives the lighting generator. There are two steam stand-by units of about 350-h.p. each driving shunt-wound generators.

The Mather and Platt engine drives a 200-k.w. Mather and Platt generator with cast-steel frame by means of square-section hemp ropes; the Robey engine drives a 250-k.w. Siemens generator also by square ropes; the Hornsby Stockport engines drive by means of belts B.[ritish] T.[homson] H.[ouston] 150-k.w. generators.

These four generators are coupled in parallel, and successfully share the peak loads occasioned by the large intermittent haulages without overloading any one machine. The pressure is 550 volts.

The calorific value of the gas employed is 400 B.T.U. (high value); the compression in the engine cylinders is 100lbs to the square inch. The gas is purified from sulphur, ammonium chloride, tar, and benzol, and passes through ferric oxide purifiers and Cripp’s washer.

Screens are erected on the pit bank, and are of the Zimmer type, which at present are steam driven.

The washery is of the Luhrig type, and is steam driven. A belt conveyor 90 yards long conveys the washed slack [coal] to the by-product ovens.

The Coke Ovens are in two batteries of 37 and 8 ovens respectively; they are of the horizontal flue Simon Carvès type; in the smaller battery each oven has its own separate flues. An electric ram has recently been installed.

About 800 tons of coke are produced per week from these ovens, and 15 tons of ammonium sulphate, ammonium chloride, tar, and benzol are also recovered.

Four boilers are fired by a mixture of waste and live gas.

There are about 140 beehive coke ovens from which coke only is obtained. Five boilers are fired by the waste heat.

Lamps

The lamps in use are of the Mueseler type, and have proved thoroughly reliable. The lead rivet is in universal use throughout the pit; no re-lighting is performed.

Ambulance and rescue apparatus houses are provided.

A Brick Yard is run in connection with the pit, as excellent fireclay is available.

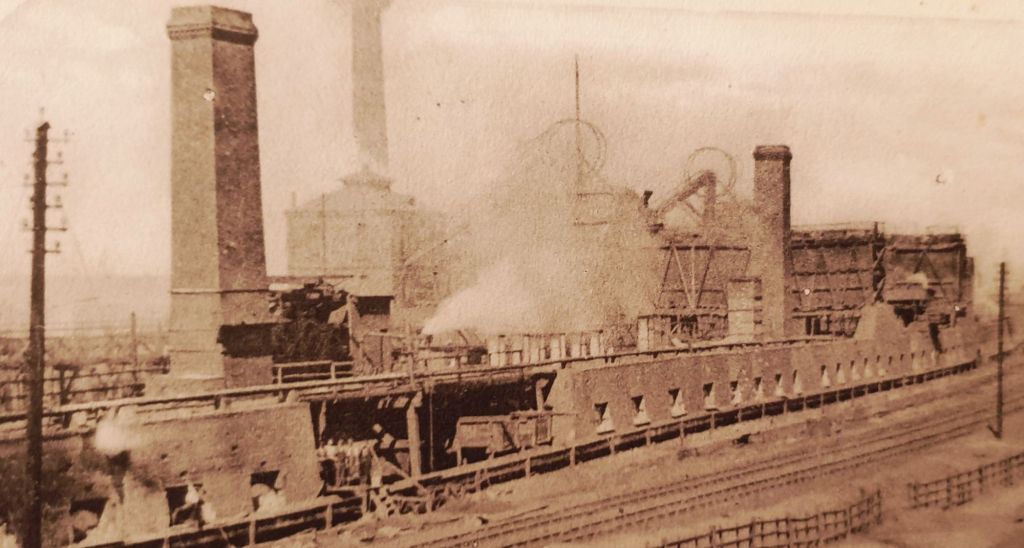

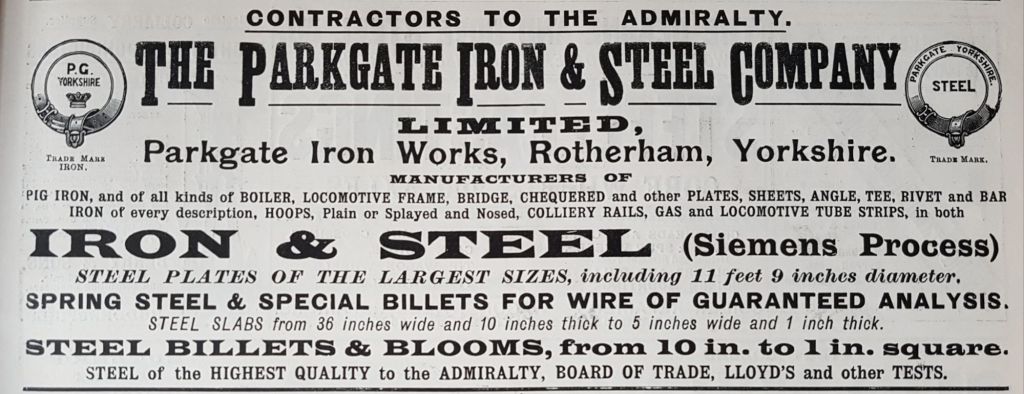

The Park Gate Iron and Steel Company Limited, Rotherham

The works of this firm are the oldest and most extensive of their class in the district. They were commenced on a small scale in 1823 by two gentlemen from Sheffield. They passed through the hands of several owners, and were at one time known as the Birmingham Tin Plate Works. Subsequently they came into the possession of Messrs. Samuel Beale & Co., from whom they were purchased in 1864 by the present owners.

At that time the staple industry was the manufacturer of iron rails, large quantities of which were supplied to the leading railways, both at home and abroad. It is worthy of note that a quantity of these rails for use on the Metropolitan Railway were case-hardened on the head for the purpose of increasing their durability. After the introduction of the Bessemer process, however, the manufacture of iron rails on a large scale ceased, and the works were adapted for other purposes.

It was at these works that the original trials were made of ironstone from the present field of Lincolnshire ore at Frodingham.

When larger plates began to be used for purposes of construction, Messrs Beale & Co. erected plate mills, which were certainly large for their time, and in these mills the plates for the steamship “Great Eastern” were rolled. Another point of great historical interest is that rolled armour plates were first made at these works. The experience gained in rolling the large plates for the “Great Eastern” encouraged the firm to undertake the manufacturer of armour plates; and for nearly five years rolled armour plates were obtainable only from the Parkgate works.

Up to the year 1888 the Company manufactured wrought iron only, but in that year the steel works were erected, and the first cast of steel was made on October 26th, 1888.

The works have been altered and improved during recent years, and are now quite modern in all appliances that make for efficiency in working and quality of product. In 1908 the Directors decided to cease making wrought iron, and the manufacture of wrought iron, which was the original industry of the firm, has now been given up entirely.

The present constitution of the works is follows:

Blast Furnaces

There are five furnaces, three at the Holmes Works, near Masbro’ Station, and two at Parkgate. The furnaces at the Holmes are of the open-top type. The two at Parkgate were erected in 1905 and 1906 to replace three old open-top furnaces which have been dismantled. The two new furnaces embody all the latest improvements in blast furnace design. The blowing engines are driven by the waste gas from the furnaces. Altogether there are four gas-driven engines, each of 700-i.h.p. Two of them are used for blowing the blast furnaces, and the other two drive the dynamos for generating electric supply for the works.

Steel Works

Both acid and basic steels, Siemens open-hearth process only, are made. There are eight 40-ton and one 60-ton melting furnaces and a 200-ton metal mixer. The plant is equipped with the most modern electrical appliances and cranes for charging the raw material direct into the furnaces instead of by hand. The rolling power of the steel works consists of a plate slabbing mill, a bloom and billet mill, and a large plate mill in which plates can be rolled up to 11½ feet wide and up to 60 feet long.

The works also comprise the following mills:-

A new 3-high plate mill, on the Lauth principle, in which plates down to ⅛ in. thick can be rolled.

Two sheet mills, in which sheets down to 18 gauge are rolled.

Three bar mills, in which bars of almost every section are rolled.

The works are also equipped with complete chemical laboratories and mechanical testing appliances.

The following is a list of the Company’s manufactures:-

Steel Plates for marine, Lancashire, locomotive, agricultural, land and other boilers; also bridge and tank plates, and checkered plates.

Steel Bars in rounds, squares, flats, angles, tees and sectional bars of all descriptions.

High Tensile Steel in plates, sheets and bars.

Slabs and Billets of dead soft quality, and guaranteed carbons.

Welding and Case Hardening Steel.

Pig Iron for foundry and forge.

Steel is supplied to the Admiralty, War Office, Board of Trade, Lloyds, English and Foreign Railways.

The total output of the works per week is over 2,000 tons of rolled and finished material. The daily consumption of fuel is about 700 tons.

The Company have their own foundry, pattern shop, fitting and machine shops, wagon repairers’, blacksmiths’ and boiler shops, &c. The Company also possess 12 locomotives and over 800 wagons. The works employ between 1,400 and 1,500 men.